Keajaiban Situs Casino Online Terpercaya: Tempat Anda Meraih Kemenangan!

Situs casino online terpercaya telah menjadi magnet bagi para penggemar judi online di Indonesia. Tidak hanya sebagai tempat hiburan semata, melainkan juga sebagai tempat yang menawarkan peluang besar untuk meraih kemenangan. Dalam artikel ini, kita akan membahas secara mendalam tentang keajaiban yang dimiliki oleh situs casino online terpercaya, serta mengungkap beberapa kunci sukses dalam mencapai kesuksesan di dunia perjudian online ini.

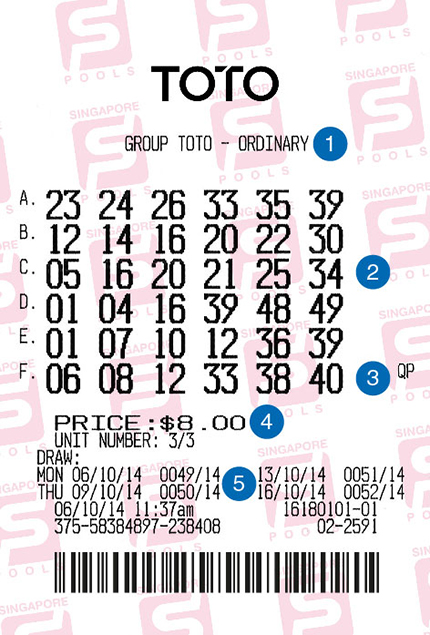

Salah satu hal yang membuat situs casino online terpercaya begitu menarik adalah keberagaman permainan yang ditawarkan. Dari permainan klasik seperti blackjack dan roulette hingga slot online yang penuh dengan kejutan, situs casino online terpercaya memiliki semuanya. Hal ini menjadikannya sebagai tempat yang cocok untuk pemain dengan berbagai preferensi dan selera. Anda dapat menemukan permainan yang sesuai dengan selera dan strategi bermain Anda, membuat pengalaman berjudi Anda semakin menarik dan mengasyikkan.

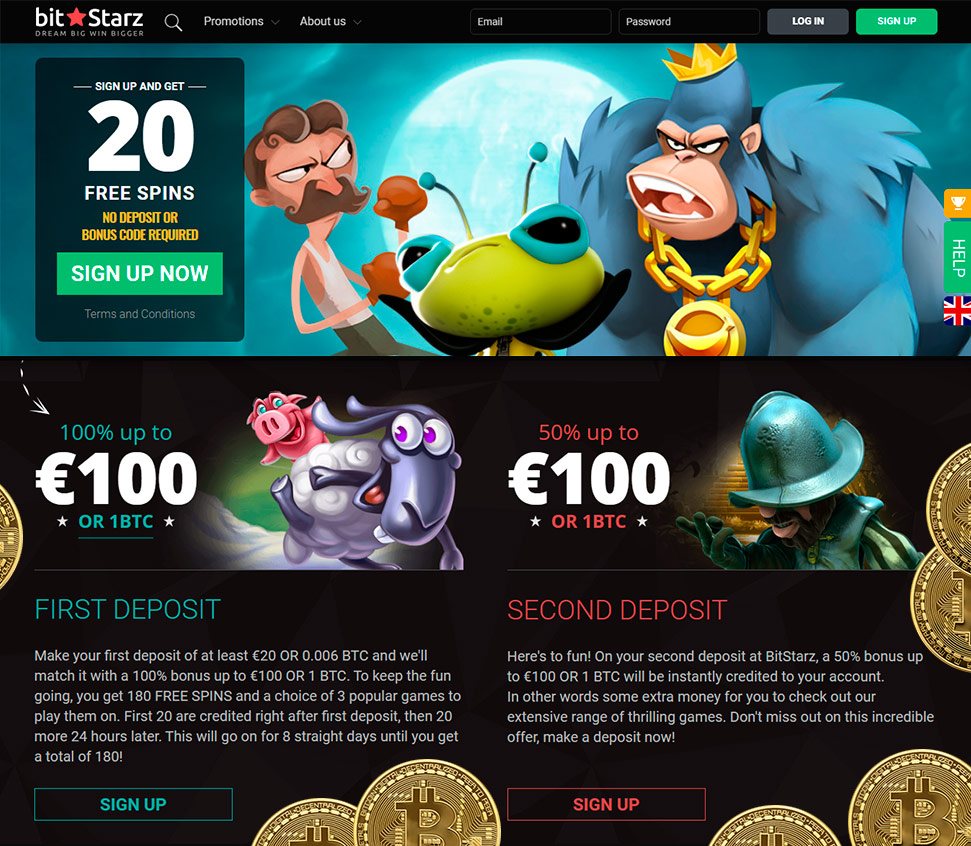

Namun, keberagaman permainan hanyalah salah satu keajaiban dari situs casino online terpercaya. Keamanan dan kepercayaan juga menjadi faktor penting yang membuat situs ini begitu diminati. Dengan adanya bandar casino online terpercaya dan agen casino online terpercaya, pemain dapat memiliki keyakinan bahwa uang dan data mereka akan diamankan dengan baik. Transaksi keuangan yang dilakukan melalui situs casino online terpercaya dijamin aman dan terjamin, sehingga pemain dapat fokus pada permainan dan meraih kemenangan tanpa kekhawatiran yang berlebihan.

Demikianlah sekilas tentang keajaiban situs casino online terpercaya yang menjadi tempat Anda meraih kemenangan. Dalam artikel ini, kita akan membahas lebih lanjut tentang keuntungan dan strategi yang dapat memberikan Anda peluang sukses di dunia perjudian online. Nova88 Login Jadilah bijak dalam memilih situs casino online terpercaya yang dapat memenuhi kebutuhan Anda, dan semoga artikel ini menjadi panduan yang bermanfaat bagi Anda dalam meraih kemenangan yang gemilang di dunia perjudian online.

Keuntungan Bermain di Bandar Casino Online Terpercaya

Pada kesempatan kali ini, kita akan membahas mengenai berbagai keuntungan yang bisa Anda dapatkan saat bermain di bandar casino online terpercaya. Sebagai pemain yang cerdas, memilih situs judi online yang terpercaya sangatlah penting, dan berikut adalah beberapa alasan mengapa Anda sebaiknya memilih bandar casino online terpercaya.

Pertama, keamanan dan kerahasiaan informasi pribadi Anda menjadi prioritas di bandar casino online terpercaya. Situs-situs ini memiliki sistem keamanan yang canggih, sehingga Anda dapat merasa tenang saat melakukan transaksi dan bermain game. Informasi pribadi Anda akan tetap terlindungi dan tidak akan disebarluaskan kepada pihak ketiga yang tidak berwenang.

Kedua, bandar casino online terpercaya menawarkan beragam permainan berkualitas tinggi. Dengan bermain di situs yang terpercaya, Anda akan dapat menikmati game-game kasino populer seperti blackjack, roulette, dan mesin slot online. Tidak hanya itu, situs-situs ini juga sering memperbarui koleksi permainan mereka, sehingga selalu ada sesuatu yang baru untuk dinikmati setiap kali Anda bermain.

Terakhir, agen casino online terpercaya juga menyediakan layanan pelanggan yang responsif dan berkualitas. Jika Anda mengalami masalah teknis, pertanyaan, atau gangguan lainnya saat bermain, tim dukungan pelanggan akan siap membantu Anda dengan cepat dan profesional. Anda dapat menghubungi mereka melalui chat live, telepon, atau email, dan mereka akan dengan senang hati menyelesaikan masalah Anda dalam waktu singkat.

Itulah beberapa keuntungan yang bisa Anda dapatkan saat bermain di bandar casino online terpercaya. Dengan memilih situs yang terpercaya, Anda akan merasa aman dan nyaman dalam menjalani pengalaman bermain judi online. Jadi, jangan ragu untuk mencoba keberuntungan Anda dan dapatkan kemenangan di situs casino online terpercaya pilihan Anda!

Kelebihan Agen Casino Online Terpercaya

-

Banyak Pilihan Permainan

Agen casino online terpercaya menawarkan beragam pilihan permainan yang dapat kita nikmati. Mulai dari permainan klasik seperti blackjack, roulette, dan poker, hingga permainan modern seperti slot online dan permainan dengan dealer langsung. Dengan begitu banyak pilihan yang tersedia, kita tidak akan pernah merasa bosan dan selalu ada sesuatu yang baru untuk di coba! -

Keamanan Data yang Terjamin

Salah satu kelebihan utama dari agen casino online terpercaya adalah keamanan data yang terjamin. Mereka menggunakan teknologi enkripsi yang canggih untuk melindungi informasi pribadi dan transaksi kita. Selain itu, mereka juga memiliki sistem keamanan yang ketat untuk mencegah akses oleh pihak yang tidak berwenang. Dengan demikian, kita dapat bermain dengan tenang tanpa perlu khawatir akan kebocoran data. -

Layanan Pelanggan yang Profesional

Agen casino online terpercaya juga menyediakan layanan pelanggan yang profesional dan responsif. Mereka memiliki tim customer service yang siap membantu jika kita mengalami masalah atau memiliki pertanyaan. Mereka dapat dihubungi melalui berbagai saluran komunikasi seperti live chat, telepon, atau email. Dengan adanya layanan pelanggan yang baik, kita akan merasa lebih terlayani dan nyaman dalam bermain di situs mereka.

Manfaat Bermain Demo Casino Online Terpercaya

Bermain demo casino online terpercaya adalah langkah yang bijaksana untuk para pemain yang ingin mengenal lebih dalam tentang permainan kasino tanpa harus mengeluarkan uang sungguhan. Dalam artikel ini, kami akan membahas beberapa manfaat yang dapat diperoleh dari bermain demo casino online terpercaya.

-

Mengasah Strategi dan Keterampilan

Dengan bermain demo casino online terpercaya, Anda dapat menguji strategi dan mengasah keterampilan sebelum benar-benar terlibat dalam permainan yang membutuhkan taruhan uang sungguhan. Anda dapat mencoba berbagai teknik dan taktik untuk melihat mana yang paling efektif dalam menghadapi berbagai situasi dalam permainan kasino. Hal ini akan membantu Anda meningkatkan peluang kemenangan Anda ketika bermain dengan uang sungguhan. -

Menjelajahi Berbagai Permainan

Bermain demo casino online terpercaya juga memberi Anda kesempatan untuk menjelajahi berbagai jenis permainan kasino. Anda dapat mencoba berbagai jenis permainan seperti slot, blackjack, roulette, dan sebagainya. Dengan mencoba berbagai permainan, Anda dapat menemukan permainan yang paling sesuai dengan minat dan preferensi Anda. Hal ini akan memungkinkan Anda menikmati pengalaman bermain kasino online yang lebih bervariasi dan memuaskan. -

Membiasakan Diri dengan Antarmuka dan Fungsi Permainan

Bermain demo casino online terpercaya juga memberi Anda kesempatan untuk mempelajari antarmuka dan fungsi permainan dengan lebih baik. Anda dapat memahami cara kerja dari masing-masing permainan, termasuk aturan, tombol-tombol yang digunakan, dan fungsinya. Hal ini akan membuat Anda lebih nyaman dan siap ketika beralih ke permainan dengan uang sungguhan. Anda akan memiliki pemahaman yang lebih baik tentang bagaimana memanfaatkan fitur-fitur permainan untuk meningkatkan peluang kemenangan Anda.

Jadi, bermain demo casino online terpercaya tidak hanya memberikan hiburan dan kesenangan semata, tetapi juga memberikan manfaat yang berharga bagi para pemain. Dengan mengasah strategi dan keterampilan, menjelajahi berbagai permainan, dan mempelajari antarmuka serta fungsi permainan, Anda dapat meningkatkan peluang kemenangan dan meraih pengalaman bermain kasino online yang lebih baik.